The Importance of Preventative Maintenance in Cold Rooms

Cold rooms are critical components in various industries, including food processing, pharmaceuticals, and biotechnology. They ensure the preservation of perishable goods by maintaining a consistent and optimal temperature. Given their crucial role, it’s essential to implement a robust preventative maintenance program to ensure cold rooms operate efficiently and reliably. This blog explores the importance of preventative maintenance in cold rooms and provides insights into best practices.

At Excel Cooling Services, Newcastle West, Co. Limerick, we recognise the critical nature of preventative maintenance and we offer 24-hour customer service to address any issue, at any time.

1. Ensuring Optimal Performance

Preventative maintenance is vital for maintaining the optimal performance of cold rooms. Regular checks and servicing of refrigeration units, insulation, and door seals help prevent temperature fluctuations, which can compromise the integrity of stored goods. By ensuring that all components are functioning correctly, businesses can avoid costly downtimes and ensure that their cold rooms are always ready for use.

2. Extending Equipment Lifespan

Cold room equipment, such as compressors and condensers, is expensive to replace. Regular maintenance helps in identifying and addressing minor issues before they escalate into major problems, thereby extending the lifespan of the equipment. This not only saves money on replacements but also reduces the frequency of repairs, leading to significant cost savings over time.

3. Energy Efficiency and Cost Savings

A well-maintained cold room operates more efficiently, consuming less energy. Dirty coils, worn-out seals, and inefficient compressors can cause the refrigeration system to work harder than necessary, leading to increased energy consumption and higher utility bills. Regular maintenance ensures that all components are clean and functioning optimally, which enhances energy efficiency and reduces operational costs.

4. Preventing Product Loss

In industries that rely on cold storage, product loss due to equipment failure can be devastating. Spoiled food, compromised pharmaceuticals, and damaged biological samples not only lead to financial losses but can also harm a company’s reputation. Preventative maintenance helps in early detection of potential issues, reducing the risk of unexpected failures and product loss.

5. Compliance with Regulations

Many industries are subject to strict regulations regarding the storage of perishable goods. Regular maintenance ensures that cold rooms comply with these regulations by maintaining consistent temperature control and hygiene standards. Non-compliance can result in hefty fines and legal issues, making preventative maintenance not just a best practice, but a regulatory necessity.

6. Safety and Reliability

Faulty cold room components can pose safety risks, such as refrigerant leaks or electrical failures. Regular inspections and maintenance help identify and rectify potential hazards, ensuring a safe working environment for employees. Reliable cold room operations also instill confidence in stakeholders and customers, knowing that the business prioritizes safety and quality.

Here at Excel Cooling Services, we’re all about making sure you’re covered, day or night. It’s not just about fixing problems; it’s about being the reliable partner you need, whenever you need us. We really understand how crucial our role is in keeping your operations smooth. Every time you reach out, it’s our moment to prove our dedication to excellence and to let you know that you’re not alone. We’re here to support you, every step of the way.”

Comprehensive Support, Day or Night

Our 24-hour customer service encompasses a wide range of support, from troubleshooting and remote assistance to on-site repairs and emergency services. We’re here to ensure that any issue you face is resolved quickly and effectively, with minimal impact on your operations.

This round-the-clock support is part of our holistic approach to customer service, ensuring that we’re not just a service provider but a trusted partner in your business’s continued success.

Your Reliable Partner in System Maintenance and Support

At Excel Cooling Services, we don’t just respond to emergencies; we prevent them. Our 24-hour service includes regular maintenance and monitoring, helping to identify and rectify potential issues before they become problems. This proactive approach ensures that your Refrigeration, Air-Conditioning, and Heat Pump Systems are always in top condition, ready to support your business’s needs at all times.

Best Practices for Preventative Maintenance

To maximise the benefits of preventative maintenance, consider the following best practices:

- Schedule Regular Inspections: Establish a routine maintenance schedule that includes daily, weekly, monthly, and annual inspections.

- Keep Detailed Records: Maintain logs of all maintenance activities, including the date, performed tasks, and any issues identified.

- Train Staff: Ensure that staff members are trained to perform basic maintenance tasks and recognize signs of potential problems.

- Use Quality Parts: When replacing components, use high-quality parts that meet the manufacturer’s specifications.

- Work with Professionals: Partner with qualified HVAC technicians and refrigeration experts for comprehensive maintenance and repairs.

If you would like to learn more about Excel Cooling Services‘ services for Refrigeration, Air-Conditioning for the commercial and industrial sectors, and Heat Pumps Air-To-Air and Air-To-Water for both the domestic and commercial sectors why not book a callout to your premises and one of our team will discuss your maintenance requirements.

Click here to download our brochure to learn more about our services!

Related posts

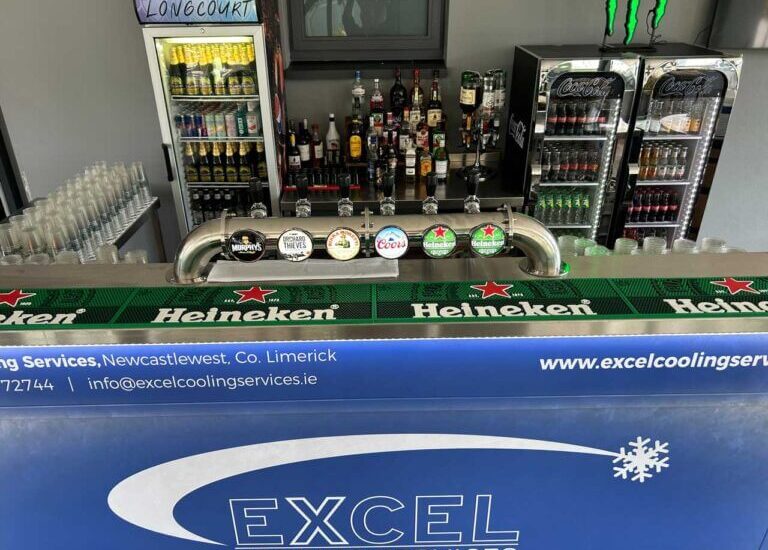

Mobile Bar Rental

Mobile Bar Rental 8 Sustainable Practices for Mobile Bars to Reduce Environmental Impact

Refrigeration

Refrigeration Essential Refrigeration for Food Safety in Irish Businesses

Air Conditioning

Air Conditioning